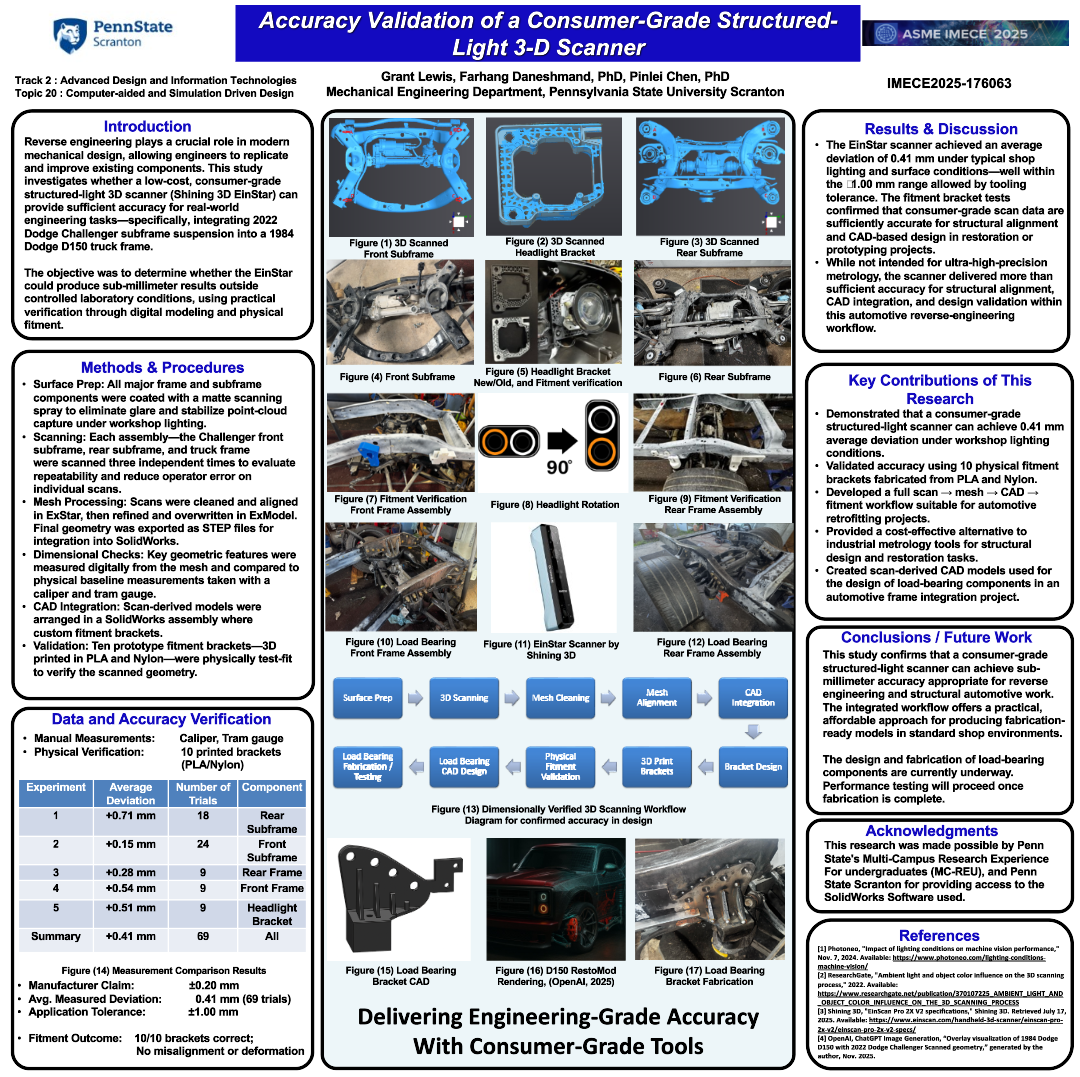

Accuracy Validation of a Consumer-Grade Structured-Light 3D Scanner

Figure (1) EinStar 3D Scanner by Shining 3D

Project Overview

This undergraduate research project investigated whether a consumer-grade structured-light 3D scanner could produce geometry with sufficient accuracy and repeatability for engineering design, CAD integration, and fabrication of load-bearing components under non-ideal, real-world conditions.

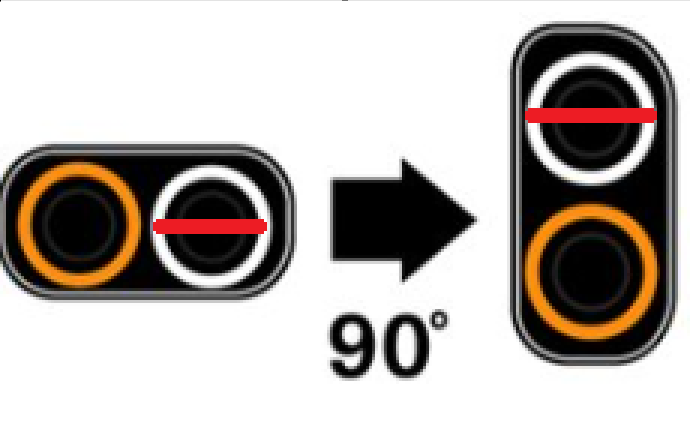

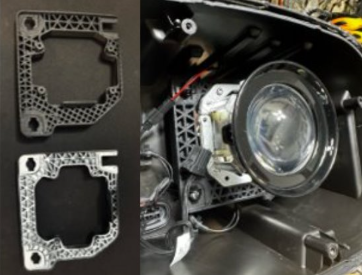

Beyond controlled measurement comparisons, the research was intentionally grounded in a real engineering application: the reverse engineering and integration of modern suspension and frame components from a Dodge Challenger into a legacy vehicle platform (1984 Dodge D150). The secondary application was a small-scale reverse engineering of plastic components to rotate a projector housing by 90 degrees, allowing a horizontal beam pattern after rotating the headlight assembly to the vertical configuration. Scanned geometry was used to generate CAD models that directly informed the design and fabrication of structural brackets and mounting interfaces, allowing scanner performance to be evaluated through physical fitment and installation, not solely numerical error metrics.

By linking digital scanning accuracy to real-world mechanical integration, the work assessed whether consumer-grade scanning tools can reliably support practical engineering workflows in automotive modification, restoration, and prototyping contexts.

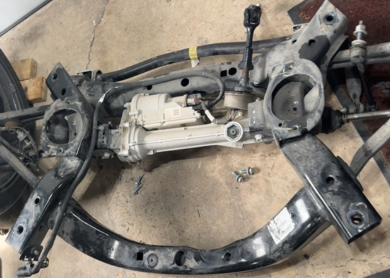

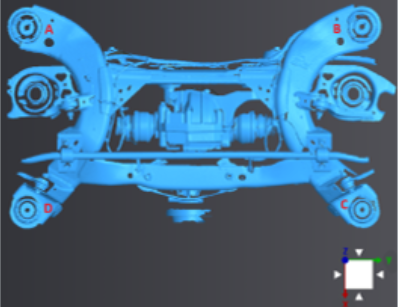

Figure (2) Front Subframe

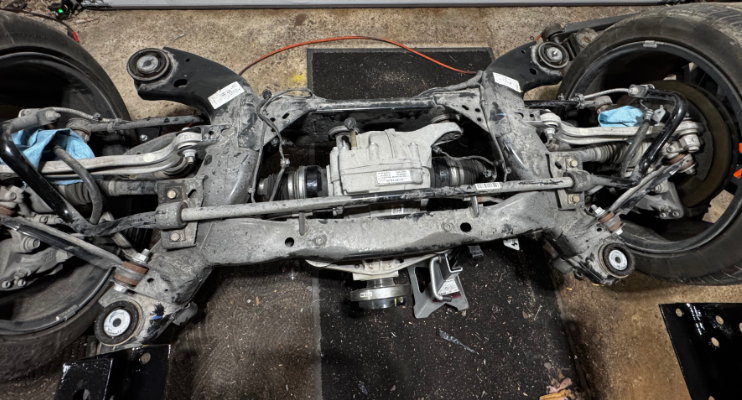

Figure (3) Rear Subframe

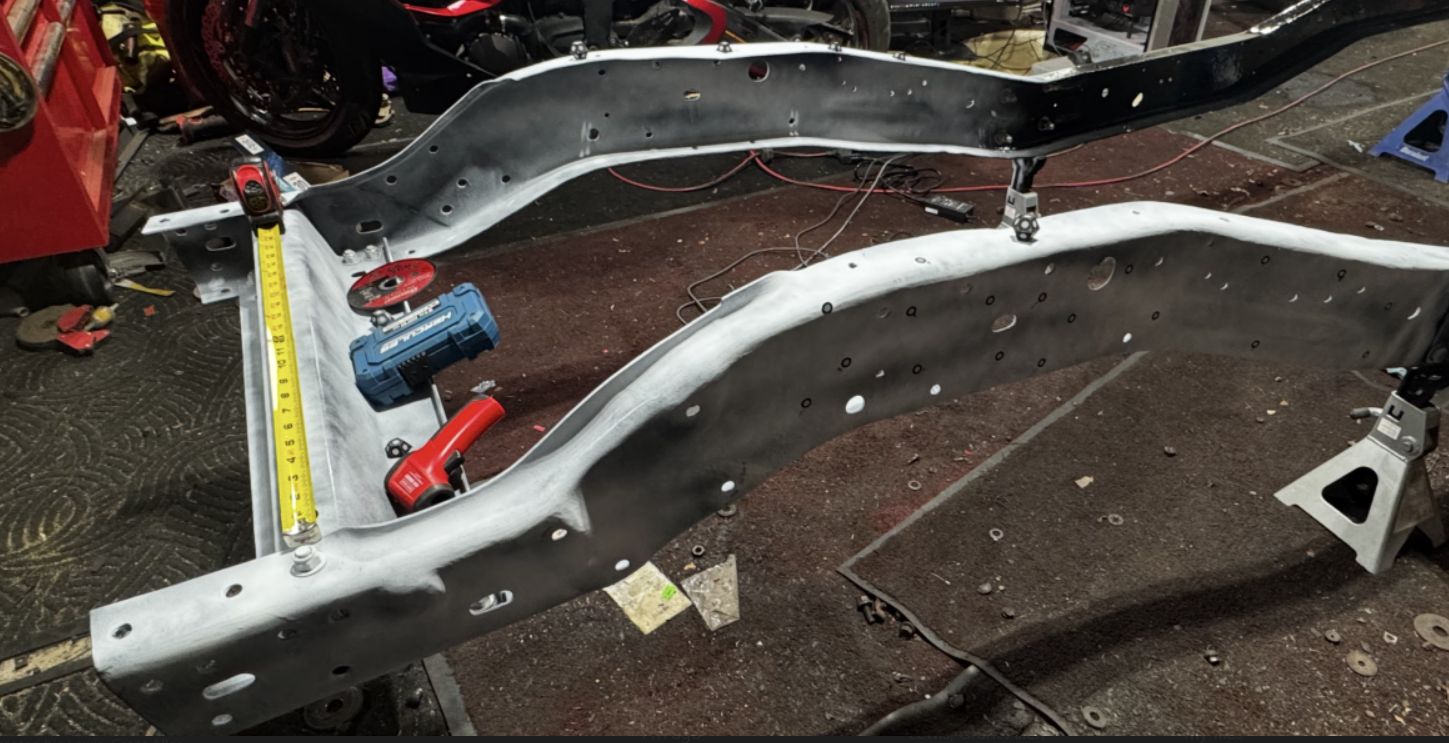

Figure (4) Front D150 Frame

Methods & Experimental Approach

The research methodology combined digital scanning, manual metrology, and physical validation:

Surface preparation using removable matte spray to improve scan fidelity

Controlled scanning of major automotive components (front subframe, rear subframe, frame sections, brackets)

Multiple independent scans to evaluate repeatability and operator sensitivity

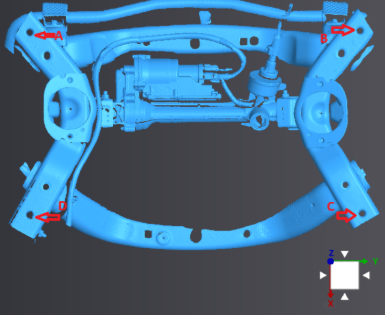

Mesh cleanup, alignment, and dimensional analysis in CAD software

Comparison of scan-derived dimensions against physical baseline measurements

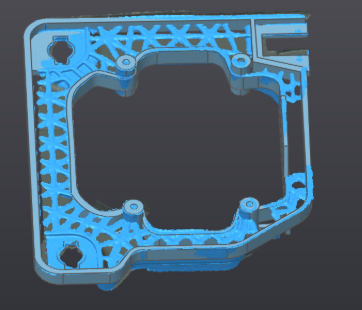

Design and fabrication of custom titment brackets based directly on scanned geometry and 3D printed

Physical fitment verification within an actual vehicle assembly

This hybrid workflow ensured that scanner accuracy was evaluated not only numerically, but also functionally, through real mechanical integration.

Figure (5) Rear D150 Frame

Figure (6) Front Subframe 3D scan

Figure (7) Rear Subframe 3D scan

Figure (8) Headlight Bracket

Figure (9) Headlight Beam Pattern Modification

Figure (10) Projector beam mounting bracket

Research Objectives

The primary objectives of this research were to:

Quantify the dimensional accuracy and repeatability of a consumer-grade structured-light scanner

Compare scanned geometry against manual baseline measurements (caliper and tram gauge)

Evaluate whether scanner-derived CAD models are suitable for load-bearing component design

Validate scanner performance through physical fitment testing, not just numerical error metrics

Assess applicability within automotive reverse-engineering and restoration workflows

Key Results

Average measured deviation: ±0.41 mm across 69 total trials

Manufacturers claimed accuracy: ±0.20 mm

Allowable tolerance: ±1.00 mm (Due to tooling accuracy ratings)

Fitment success:

10/10 prototype brackets fit correctly

No observed misalignment or deformation during installation

While the scanner is not intended for ultra-high-precision metrology, results demonstrated that it is sufficiently accurate for structural layout, bracket design, and CAD-to-fabrication workflows when used with proper validation procedures.

Figure (11) Old bracket (White), Correct beam pattern bracket (Black), Final Assembly

Figure (12) Front Frame Fitment Verification Assembly

Figure (13) Rear Frame Fitment Verification Assembly

Engineering Significance

This research demonstrates that consumer-grade scanning tools, when combined with sound engineering judgment and verification methods, can:

Reduce dependency on expensive industrial scanning systems

Enable accurate CAD reconstruction in constrained or non-ideal environments

Support real structural design work in automotive and mechanical applications

Bridge the gap between digital modeling and physical fabrication

The validated workflow provides a practical, cost-effective approach for engineers working in restoration, motorsports, prototyping, and small-scale manufacturing contexts.

Recognition & Awards

Third Place – ASME International Mechanical Engineering Congress & Exposition (IMECE 2025)

The research project “Accuracy Validation of a Consumer-Grade Structured-Light 3D Scanner” was presented at the American Society of Mechanical Engineers (ASME) International Mechanical Engineering Congress & Exposition, a major international engineering research conference, where it earned Third Place in the undergraduate research poster competition.

Researcher’s Choice Award – Penn State Multi-Campus Research Experience for Undergraduates (MC-REU), 2025

Awarded for “Accuracy Validation of a Consumer-Grade Structured-Light 3D Scanner” based on top faculty evaluations across the MC-REU program, recognizing technical rigor, research quality, and independent contribution.

Figure (14) Undergraduate Research Poster