Engineering Projects

1984 Dodge D150 Modernization (392 HEMI + Challenger Subframes)

A ground-up engineering rebuild integrating modern OEM systems into a classic chassis. Work includes CAD-driven bracket design, structural fabrication, packaging and integration, and system-level planning across drivetrain, suspension, braking, HVAC, electrical, and exhaust (dual-mode valvetronic).

The project focuses on delivering modern performance, safety, and drivability within the constraints of a classic vehicle architecture.

ASME eHPVC: Human-Powered Vehicle Design & Fabrication

Design and fabrication of a competition human-powered vehicle with emphasis on mechanical design, suspension/steering kinematics, structural analysis, and manufacturability. Includes iterative CAD development, component testing, and integration for performance and reliability under competition constraints.

Residential Elevator System Design

Mechanical design and analysis of a residential elevator/lift system focused on accessibility, safety, code constraints, and defined load requirements. The project emphasizes conservative engineering assumptions and real-world applicability.

Awards: First Place – Penn State Scranton Undergraduate Research Fair; First Place – Penn State Eastern Regional Undergraduate Research Symposium (Brandywine)

Undergraduate Research: 3D Scanning Accuracy Validation

Research evaluating the dimensional accuracy and repeatability of a consumer-grade structured-light 3D scanner using baseline measurements, repeated trials, CAD comparison, and real-world validation through engineered fitment.

Awards:

ASME IMECE 2025 – Third Place (International Conference)

Penn State MC-REU 2025 – Researcher’s Choice Award

1984 Dodge D150 — Full Vehicle Systems Engineering Project

Project Overview

This project involves the full systems-level modernization of a 1984 Dodge D150 pickup using components from a 2022 Dodge Challenger Scat Pack Widebody. The scope includes powertrain integration, suspension and subframe geometry, structural reinforcement, electrical and electronic systems integration, and drivability optimization.

The objective is not cosmetic restoration, but the engineering development of a fully functional, modernized vehicle platform capable of OEM-level performance, reliability, and serviceability within the constraints of a legacy chassis.

This project integrates all important modern systems, including:

Modern Powertrain (6.4L hemi and TR6060 6 speed manual)

Independent suspension subframe systems in front and rear

Electronic Power Steering

ABS-controlled 4 and 6-piston Brembo Brakes

Adaptive Damping Suspension

Modern 3.92 limited-slip rear differential

Modern HVAC w/ factory dash outlets and automatic controls

Power-adjustable heated leather seats

Full digital dash and modern CarPlay-compatible infotainment system

LED projector beam headlights

Valve-tronic controllable loudness exhaust system (Custom)

Electronic system modules: Power control module, Body control module, Airbag control module, etc.

1984 Dodge D150 Square body truck

Project Vehicle

Donor Vehicle

2022 Dodge Challenger Scat Pack Widebody, w/6.4L and 6-speed manual

Suspension & Subframe Engineering

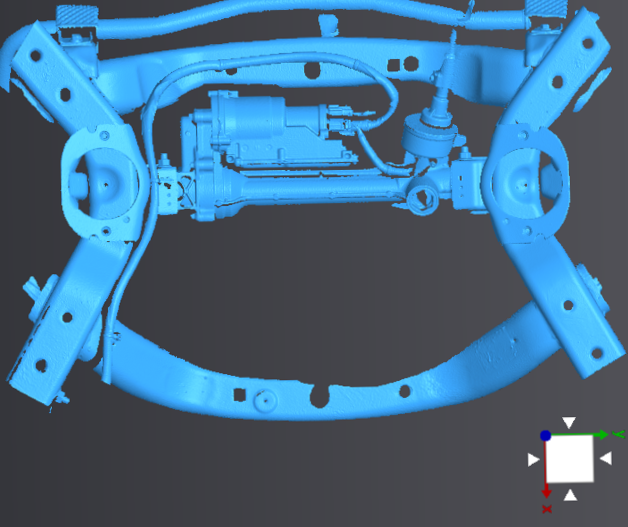

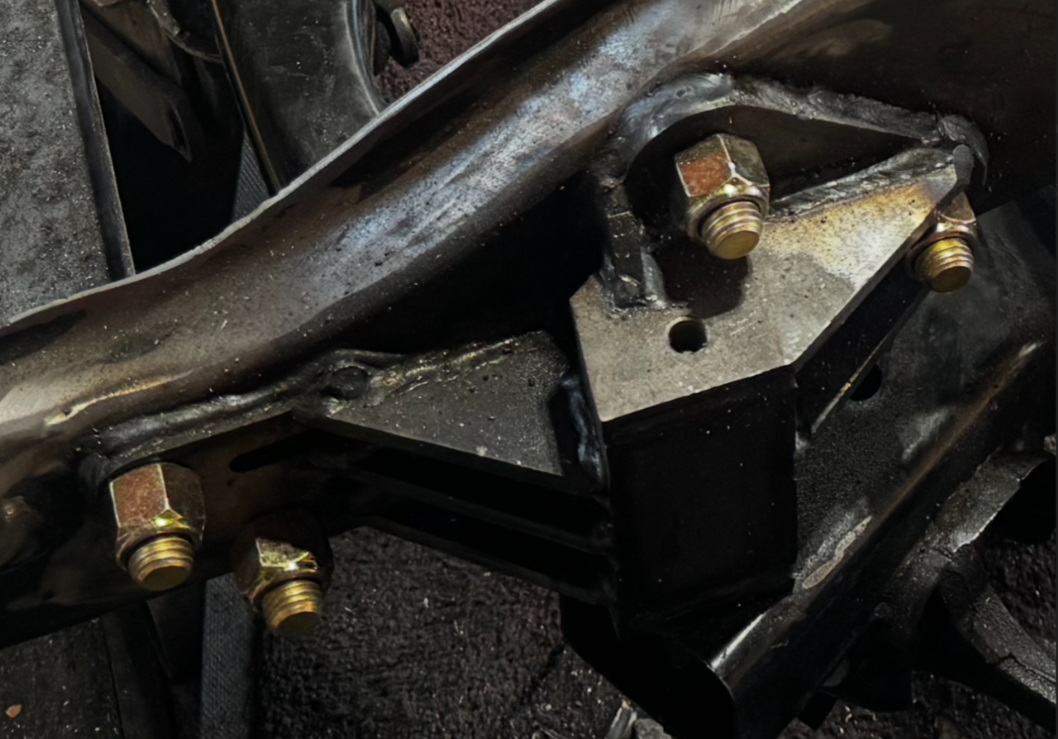

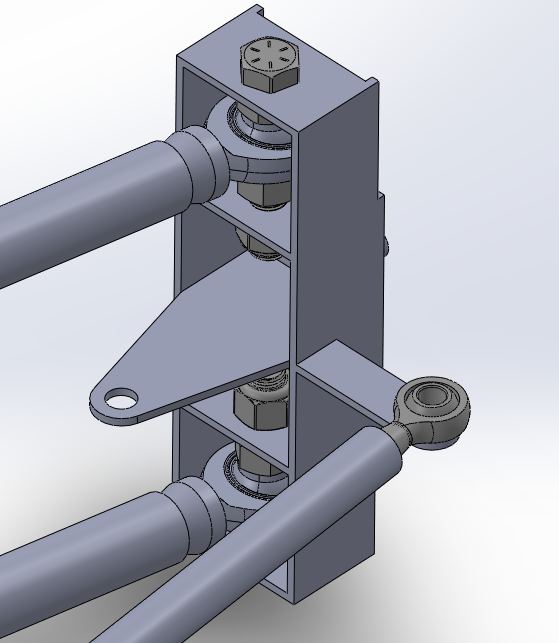

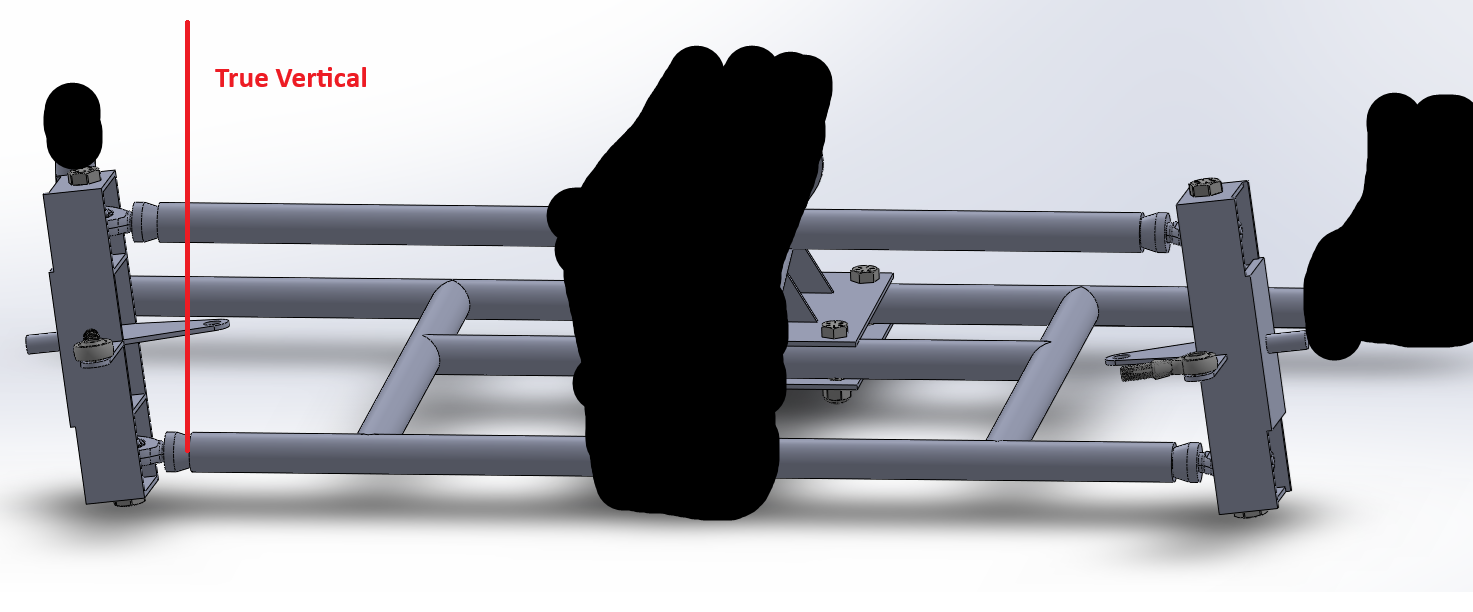

Modern Challenger front and rear subframes were integrated into the D150 frame, requiring custom mounting geometry and structural reinforcement to preserve factory suspension kinematics.

Engineering work included:

Subframe positioning and leveling

Suspension geometry analysis

Weight distribution considerations

Traction and drivability optimization

Coil-over and strut mounting structure design

The goal was to retain the handling and stability characteristics of the modern suspension system while adapting it to a fundamentally different chassis architecture.

System Architecture & Constraints

Legacy ladder-frame truck chassis (1984 D150)

Modern donor architecture (2022 Dodge Challenger ScatPack Widebody)

Fixed hard points imposed by frame geometry and cab structure

Packaging constraints for drivetrain, suspension, steering, and HVAC

Structural compatibility between unibody-derived subframes and a body-on-frame platform

This project required reconciling incompatible vehicle architectures while preserving correct suspension kinematics, drivetrain alignment, and structural load paths.

Modern Powertrain Integration

A modern 392 HEMI powertrain was integrated into the D150 chassis with attention to drivetrain alignment, mount geometry, and serviceability. Custom engine and transmission mounting solutions were developed to maintain correct driveline angles while accommodating chassis constraints.

Key considerations included:

Engine and transmission positioning

Driveshaft alignment and angularity

Clearance for exhaust, steering, and suspension travel

Structural load transfer into the frame

Powertrain’s role in the center of gravity height

Use of the Challenger fuel tank to ensure proper fuel supply, including fuel gauge and range accuracy within the OEM electronics

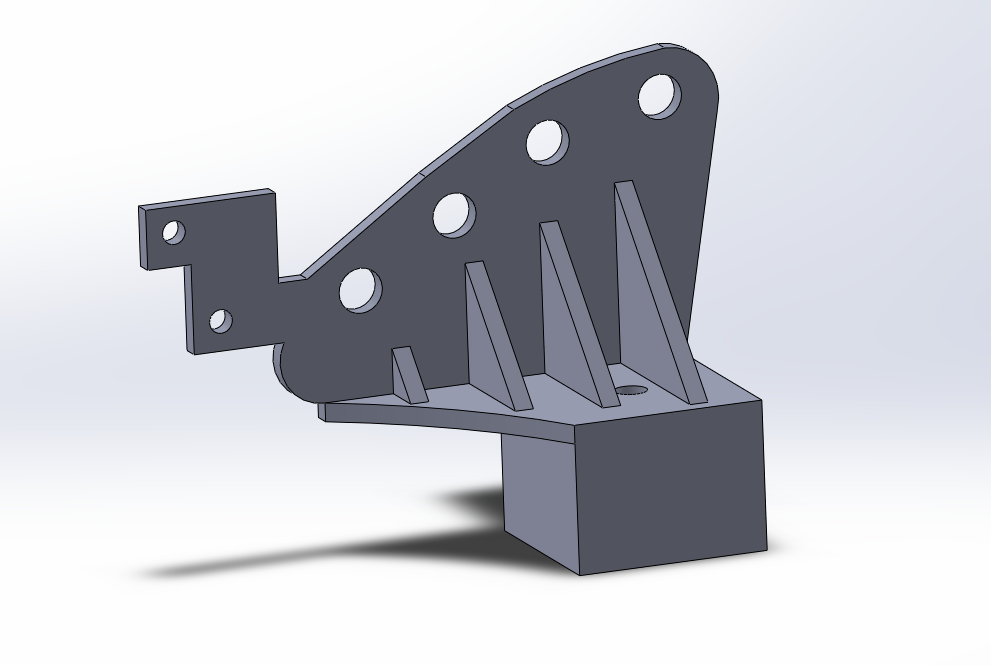

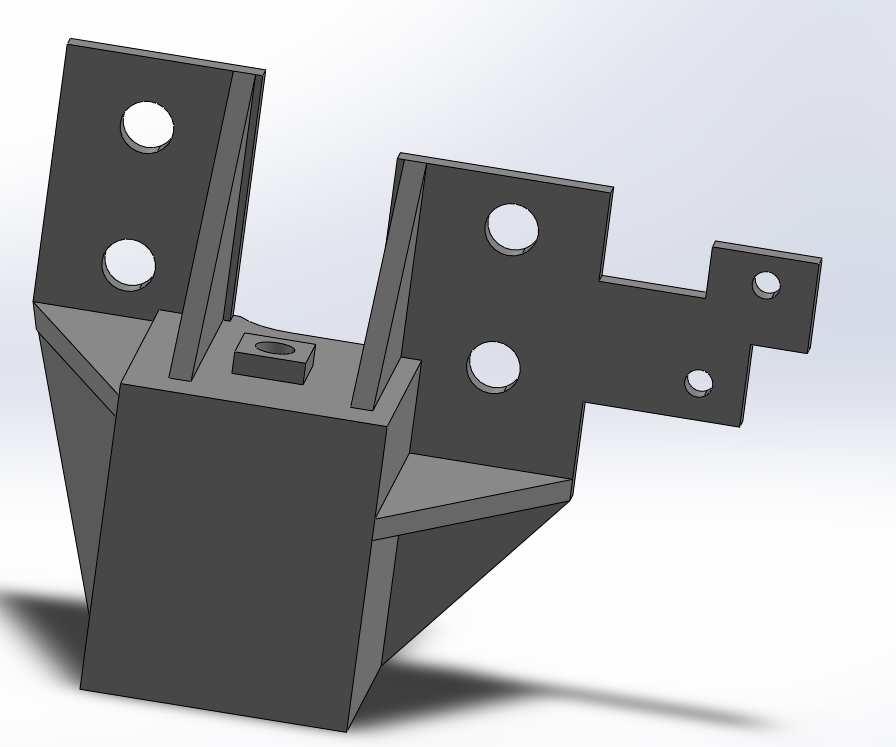

Structural Design & Fabrication

Custom structural components were designed and fabricated to support the modern suspension and drivetrain systems. These components include:

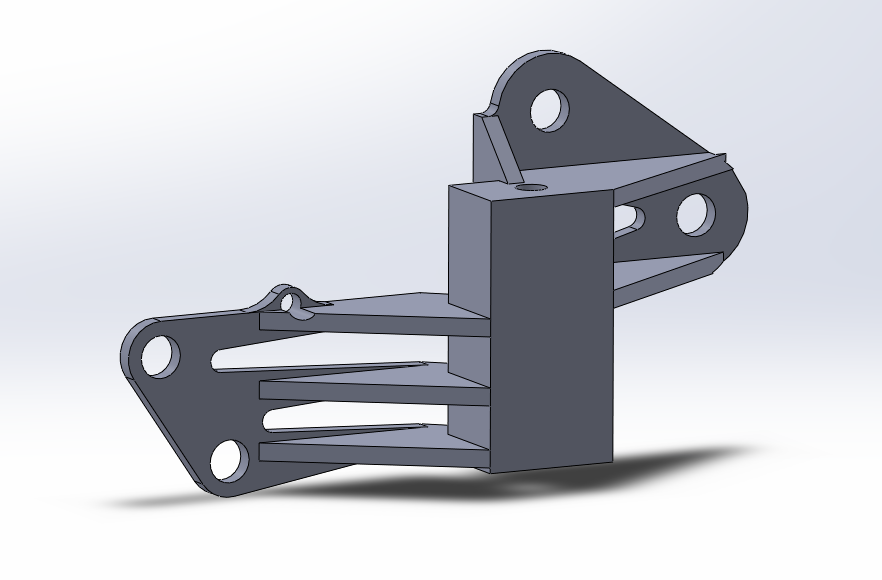

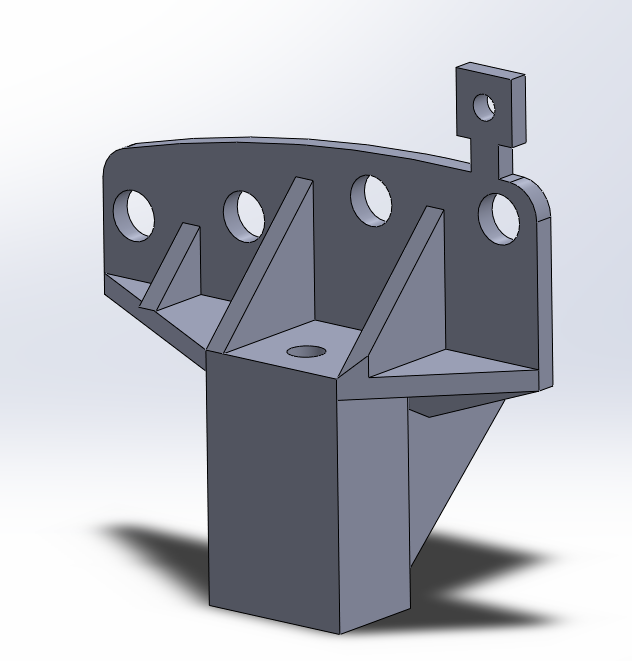

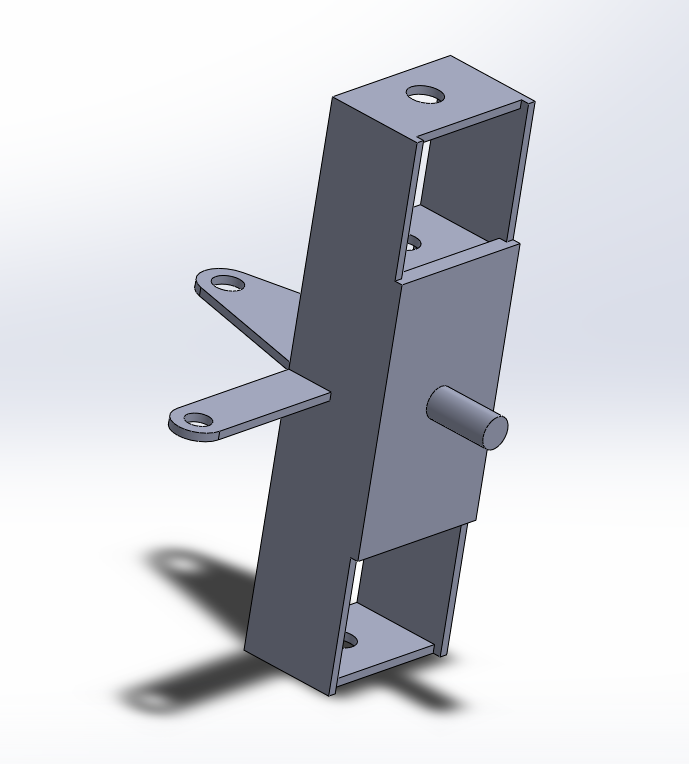

Subframe mounting brackets

Coil-over and strut support structures

Reinforcement elements for load distribution

Frame modifications required for packaging and clearance

Shortening the frame to the short bed length to best match the Challenger wheelbase

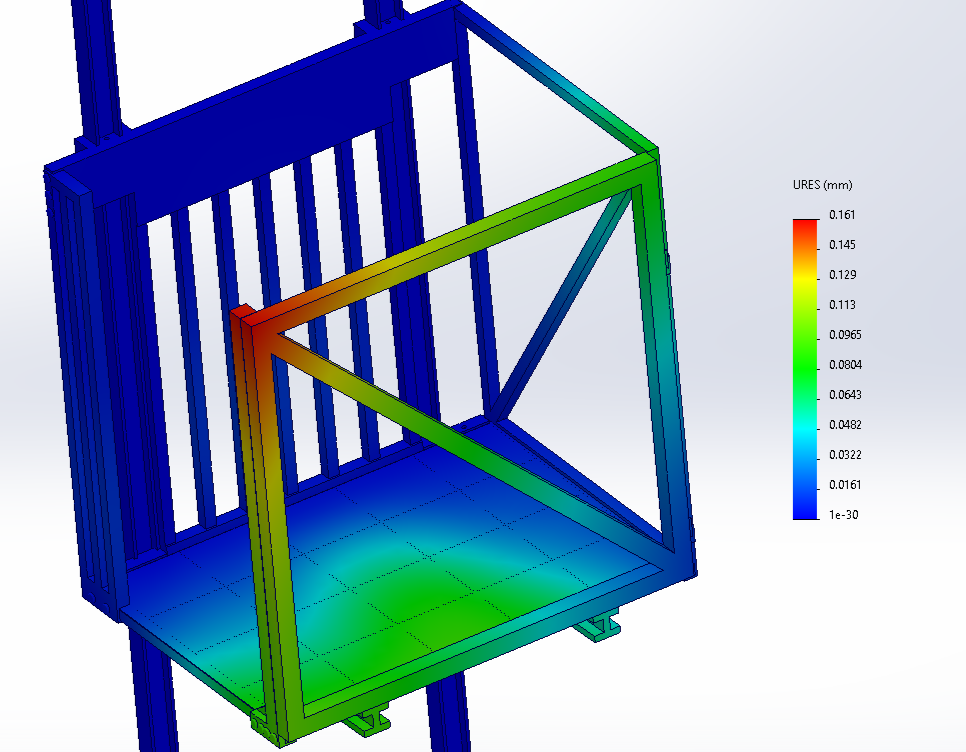

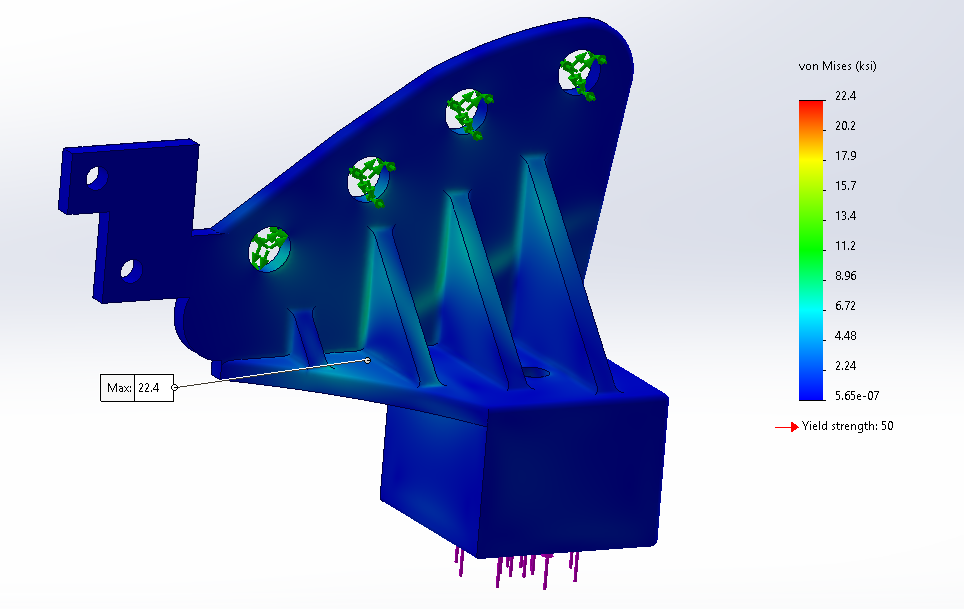

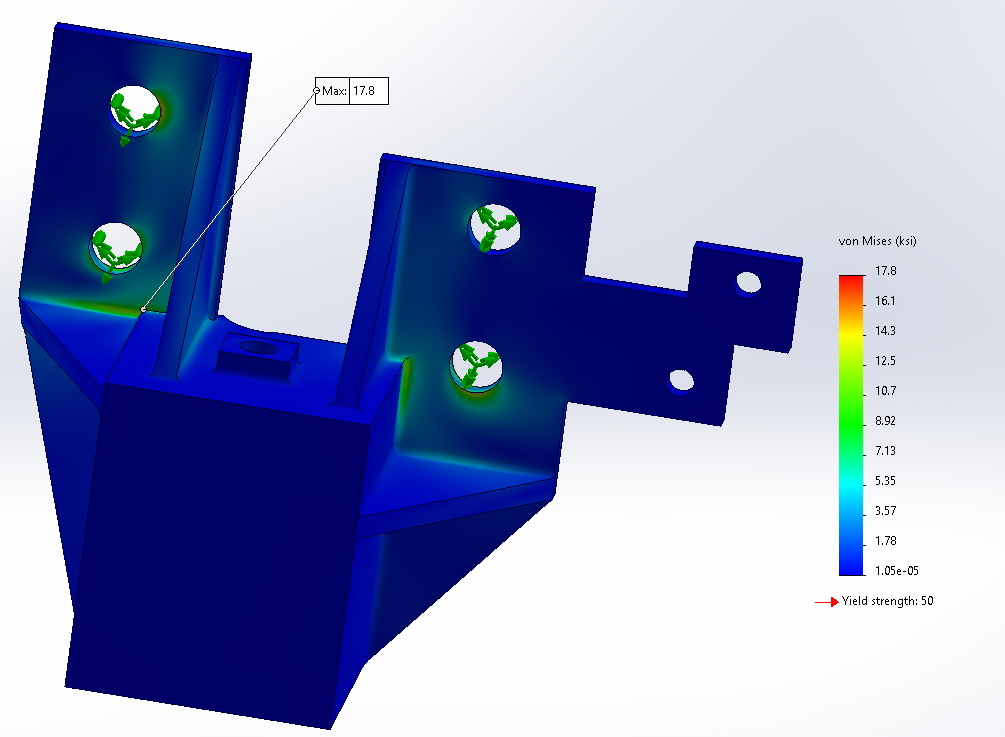

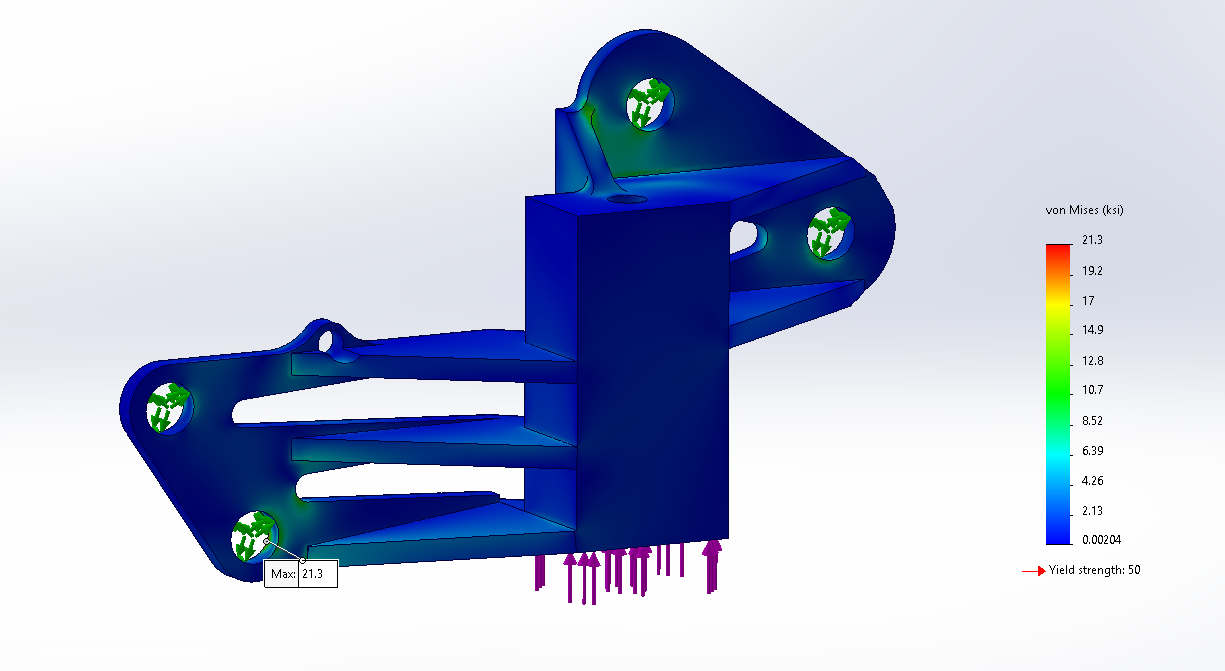

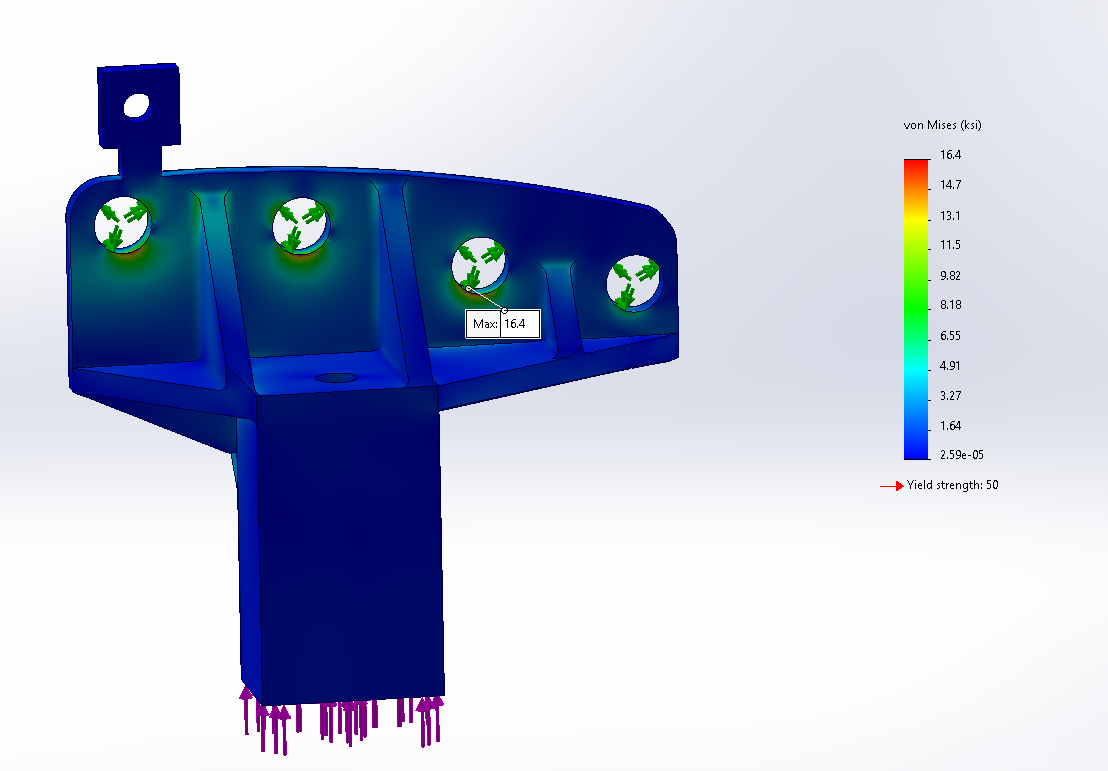

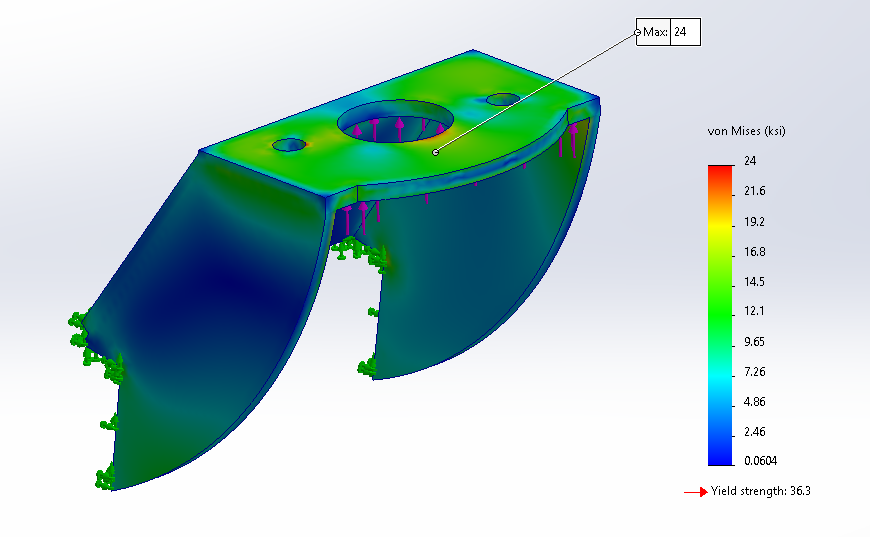

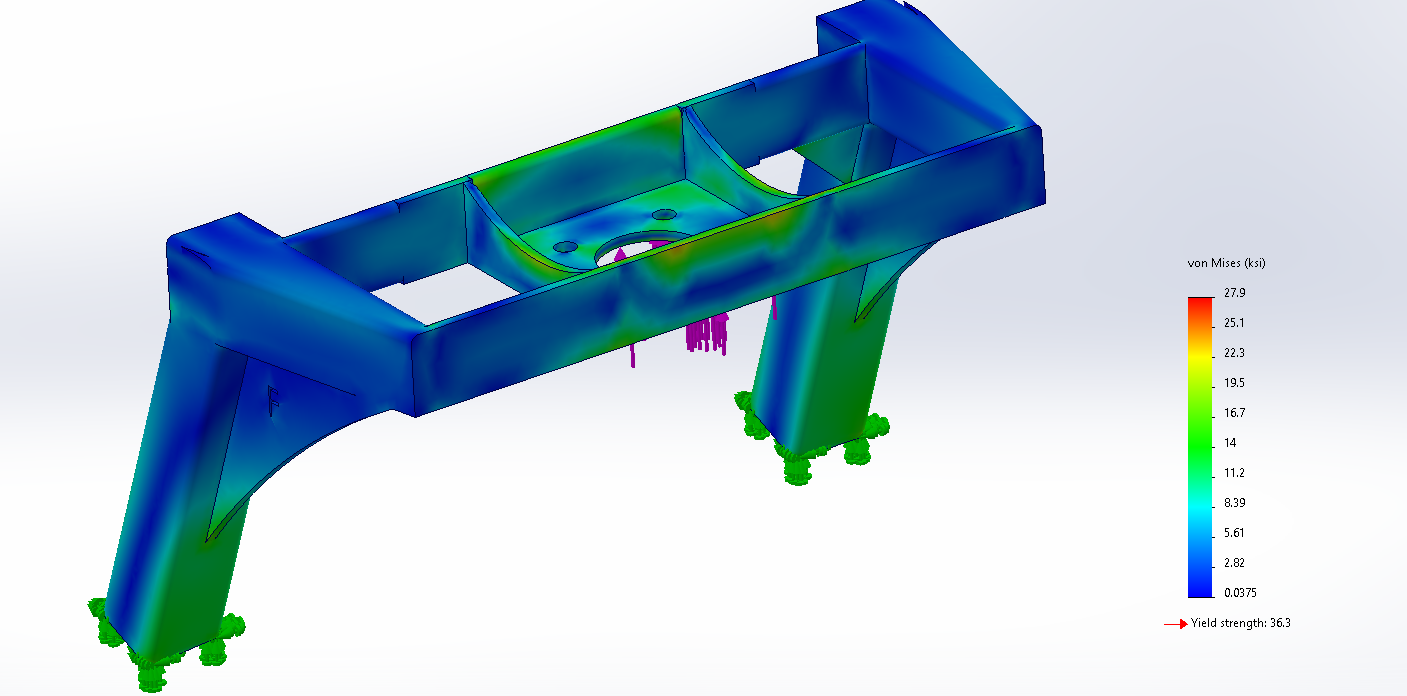

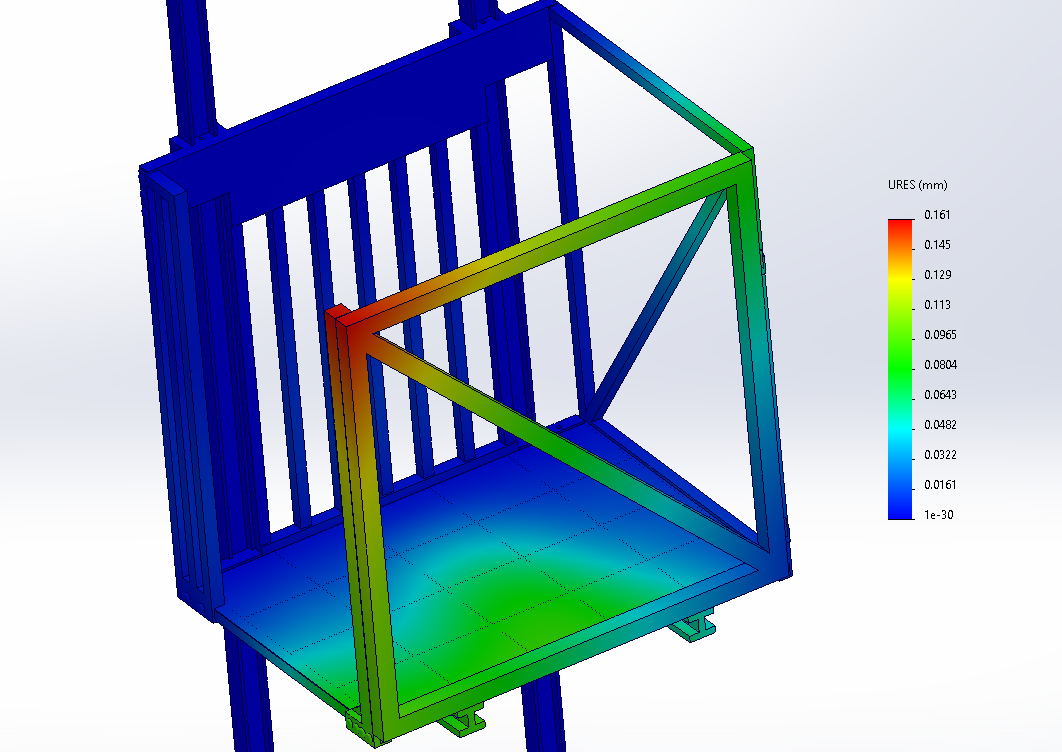

During the Finite Element Analysis, the components were subjected to the worst-case loading to ensure proper operation during extreme use. For the subframe mounting locations, they were subjected to a 1.5G lateral acceleration in both horizontal directions, as well as a 6-inch instantaneous compression of the suspension, resulting in a large upward acceleration under assumed resonance conditions.

All subframe mounting locations were fabricated out of 5/16ths thickness ASTM A572 Grade 50 plate steel to ensure rigidity and proper load transfer to the frame.

All structural work was developed with dimensions obtained from 3D scanning during my undergraduate research titled “Accuracy Validation of a Consumer-Grade Structured-Light 3D Scanner.”

CAD Design

Rear Subframe, Front Mount Design

Rear Subframe, Rear Mount Design

Front Subframe, Front Mount Design

Front Subframe, Rear Mount Design

Rear Strut Mount Design

Finite Element Analysis

Front Coilover Mount Design

Analysis of stress distribution - worst case loading

Analysis of stress distribution - worst case loading

Analysis of stress distribution - worst case loading

Analysis of stress distribution - worst case loading

Analysis of stress distribution - worst case loading

Analysis of stress distribution - worst case loading

Middle of Fabrication

During Fabrication process

During Fabrication process

During Fabrication process

During Fabrication process

During Fabrication process

During Fabrication process

Complete

Painted, Final assembly finished

Painted, Final assembly finished

Painted, Final assembly finished

Painted, Final assembly finished

Painted, Final assembly finished

Painted, Final assembly finished

HVAC System Design & Integration

The vehicle HVAC system was modified to integrate modern air conditioning and heating functionality into the legacy D150 platform while maintaining OEM-style serviceability and industry-standard interfaces.

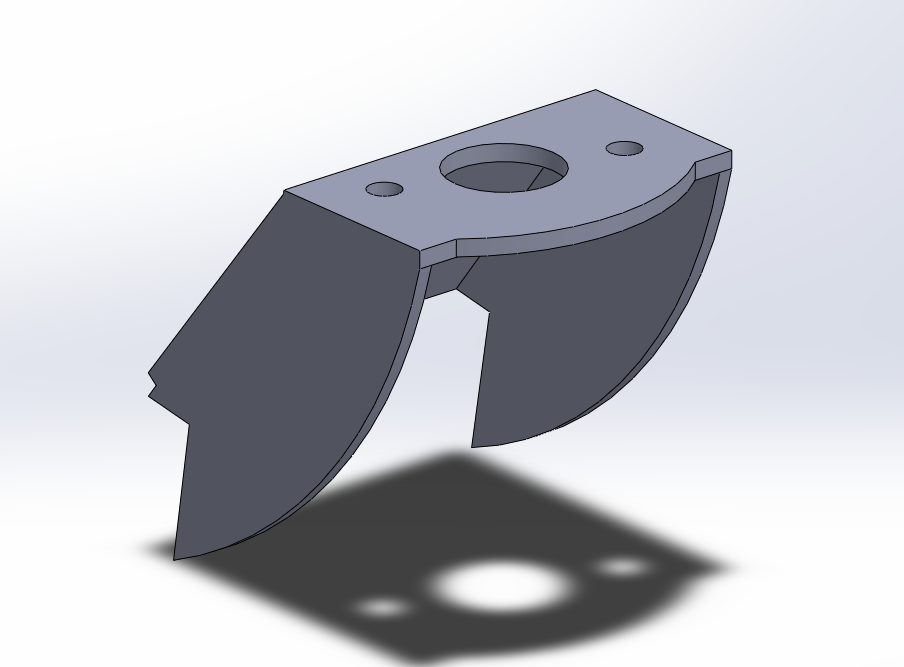

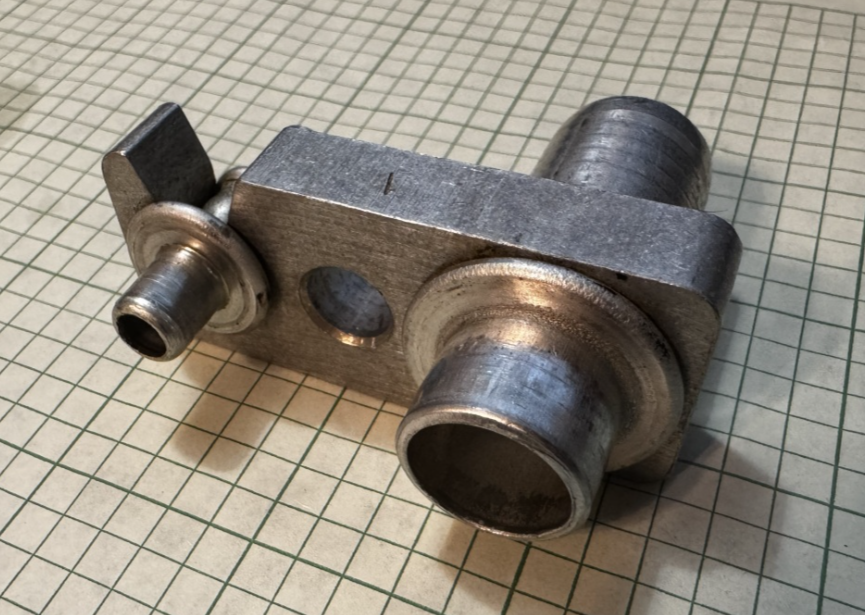

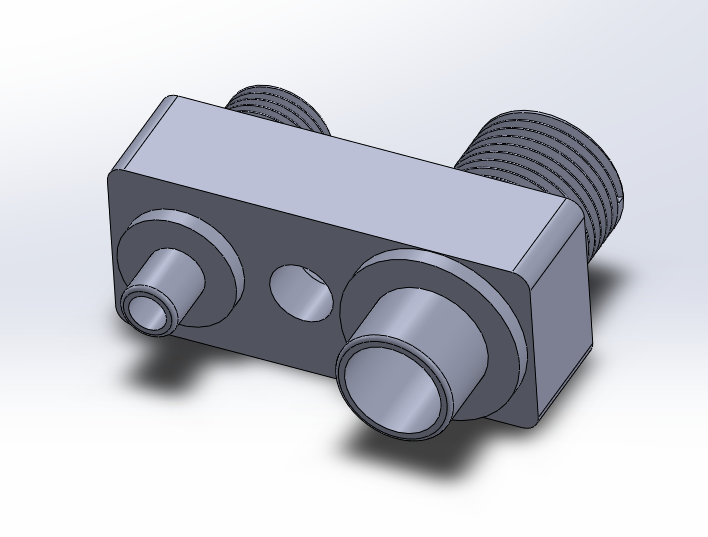

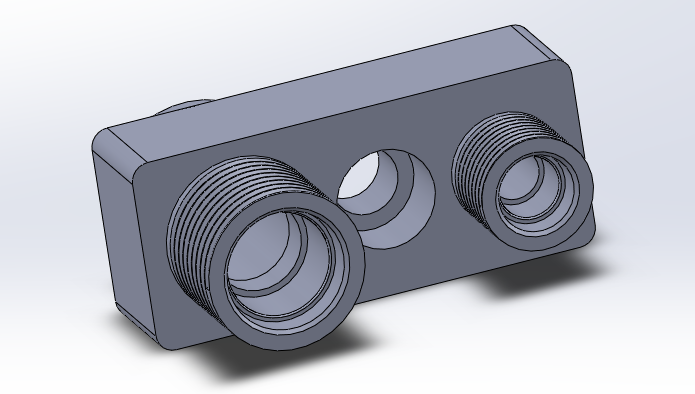

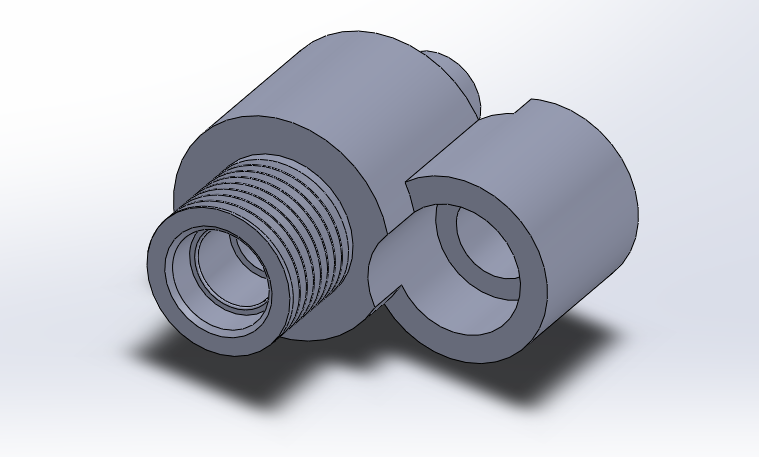

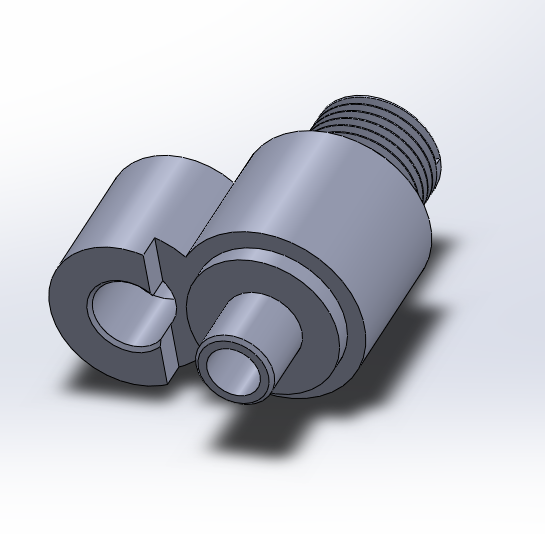

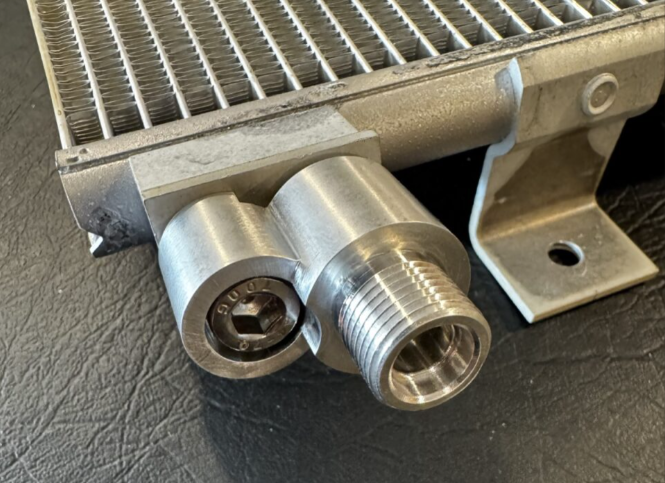

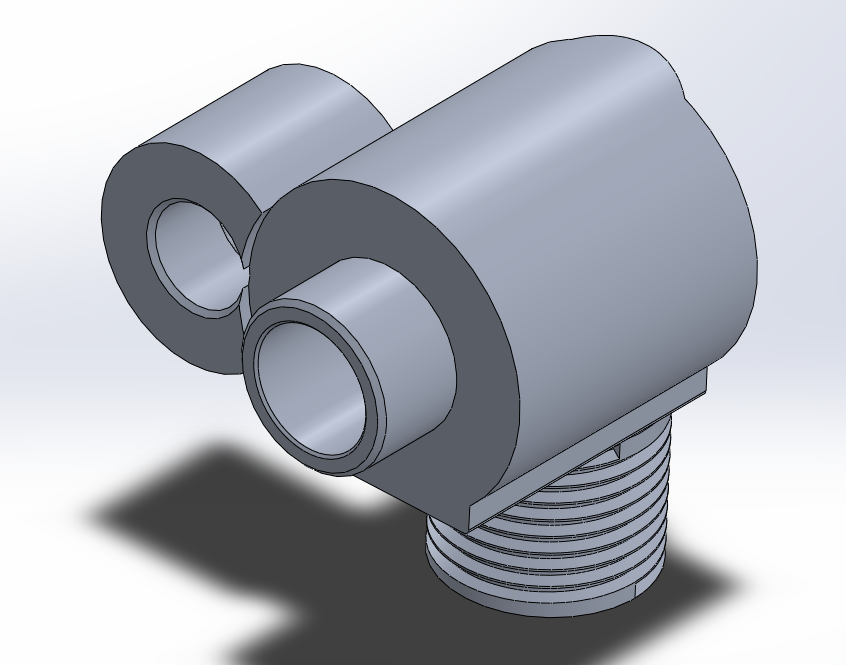

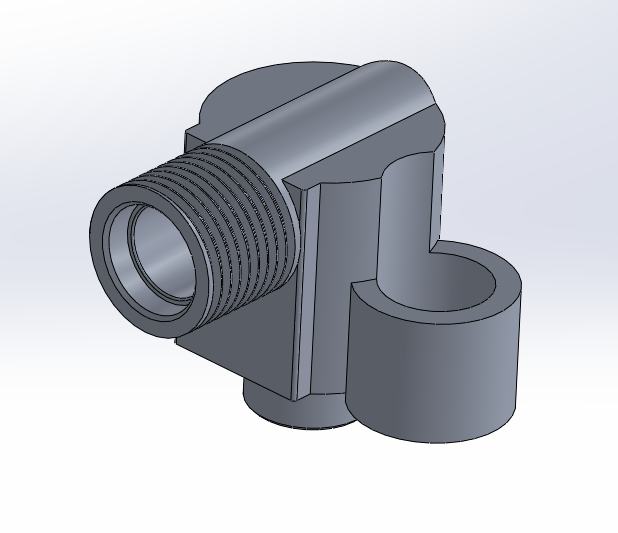

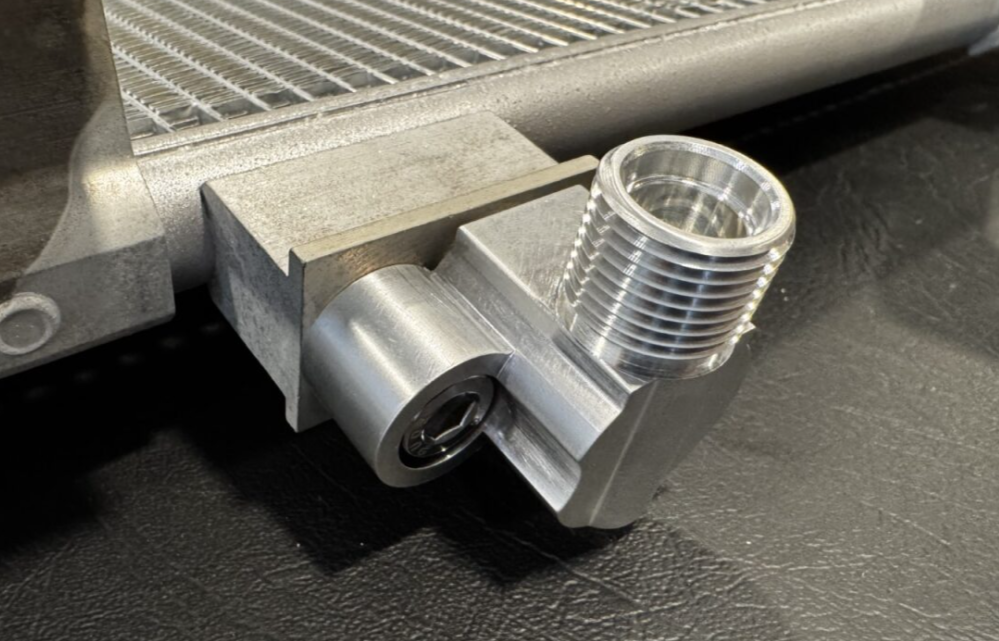

The factory fittings and A/C lines found on the Dodge Challenger were aluminum, non-threaded, O-ring, stud, and nut style fittings. The factory hard lines were not the correct dimensions due to the packaging constraints of the D150, meaning another alternative connection and hose style was required.

Rather than relying on universal or temporary fittings, the system was engineered using industry-standard threaded connections and reduced-barrier hose assemblies to ensure compatibility with modern service equipment, long-term reliability, and compliance with current automotive HVAC practices.

Fitting retention was converted from a stud/nut combination to a single hex cap screw in a recessed hole to avoid blocking the use of the threaded connections.

Key engineering considerations included:

Custom adapter design to interface modern compressors, condensers, and evaporator components with a non-native chassis

Selection and implementation of OEM-style threaded fittings and sealing strategies

Hose routing and packaging under tight engine bay and firewall constraints

Service access and future maintainability

Thermal system integration with existing engine cooling architecture

This approach prioritized repeatable serviceability, leak resistance, and professional-level integration, aligning the HVAC system with modern OEM standards rather than aftermarket conventions.

A/C Firewall connection (Liquid + Discharge)

Liquid line

Converted from Mopar Proprietary to IMACA #6 standard threaded connection

Discharge line

Converted from Mopar Proprietary to IMACA #10 standard threaded connection

Condenser - Small port (High side liquid line)

Converted from Mopar Proprietary to IMACA #6 Standard Threaded Connection

Condenser - Large port connection (Low-pressure return)

Converted from Mopar Proprietary to IMACA #8 standard threaded connection

Valvetronic Exhaust System Design

As part of the D150 modernization effort, a dual-mode valvetronic exhaust system was designed to balance daily drivability with performance-oriented sound and flow characteristics. The goal was to retain OEM-level comfort during normal operation while enabling a high-flow, aggressive exhaust path on demand.

The system utilizes electronically actuated exhaust valves to switch between two parallel exhaust paths:

Quiet Mode:

A full-length, OEM-style exhaust configuration designed to minimize cabin noise and drone while maintaining acceptable backpressure for street use.Performance Mode:

A straight-through, low-restriction exhaust path utilizing a high-performance muffler to maximize exhaust flow and acoustic output.

Electrical & Electronic Systems Integration

Modern vehicle electronics are in the process of being integrated into the legacy platform, including:

Challenger wiring harness architecture

Electronic power steering

Adaptive damping systems

ABS-equipped braking system

OEM-style controls and diagnostics

OEM Fuel system and Electronic fuel pump w/ sensors

This requires careful planning of routing, mounting, grounding, and system interoperability to ensure reliable operation across all subsystems.

Engineering Skills Demonstrated

Systems-level mechanical integration

Suspension geometry and vehicle dynamics

Structural design and fabrication

Packaging and constraint-driven design

Electrical system integration

Long-horizon project planning and execution

Validation through real-world assembly and testing

Fabrication & Manufacturing Skills Applied

Welding

MIG welding of structural steel components

Multi-pass welds for load-bearing brackets and crossmembers

Weld joint preparation and post-weld inspection

Cutting & Material Removal

Abrasive cutting and cutoff wheel operations

Precision trimming for packaging and clearance requirements

Controlled removal of legacy frame material

Grinding & Surface Preparation

Weld bead shaping and stress-relief grinding

Surface conditioning for fit-up and coating adhesion

Edge finishing for safety and durability

Drilling & Threading (Tapping)

Precision drilling for structural and mounting features

Manual tapping of threaded holes for brackets and adapters

Thread alignment, depth control, and fastener engagement verification

Fit-Up, Fixturing, and Assembly

Component alignment prior to welding and final fastening

Iterative test-fitting to validate geometry and clearances

Assembly sequencing to preserve suspension and driveline alignment

Surface Treatment & Finishing

Cleaning and preparation for corrosion protection

Priming and painting of fabricated structural components

Final surface treatment following welding and fabrication

Fluid Line Routing & Integration

Fabrication and routing of brake, fuel, and A/C lines

Line routing to avoid heat, abrasion, and suspension interference

Integration of industry-standard fittings and serviceable connections

Current Status

The vehicle is currently undergoing body off frame reconstruction. With a focus on cab work to finish the firewall and floor structures before mounting the cab for the final time. Suspension and Drivetrain systems are complete and mounted permanently. I will continue to update this page as I progress through the staged integration and validation, with ongoing work focused on final structural completion, system verification, and drivability testing.

This project remains active and continues to evolve as systems are validated and optimized.

Anticipated verified drivability date: April 8th, 2026

ASME Human-Powered Vehicle Challenge — ASME EFx of Dallas 2026 (In progress)

Project Overview

The ASME Human-Powered Vehicle Challenge (eHPVC) is a national engineering competition focused on the design, analysis, and fabrication of a safe, efficient, and high-performance human-powered vehicle within a strict regulatory framework.

This project involves translating performance goals and competition rules into a fully realized vehicle design, balancing efficiency, safety, manufacturability, and reliability under aggressive time and budget constraints.

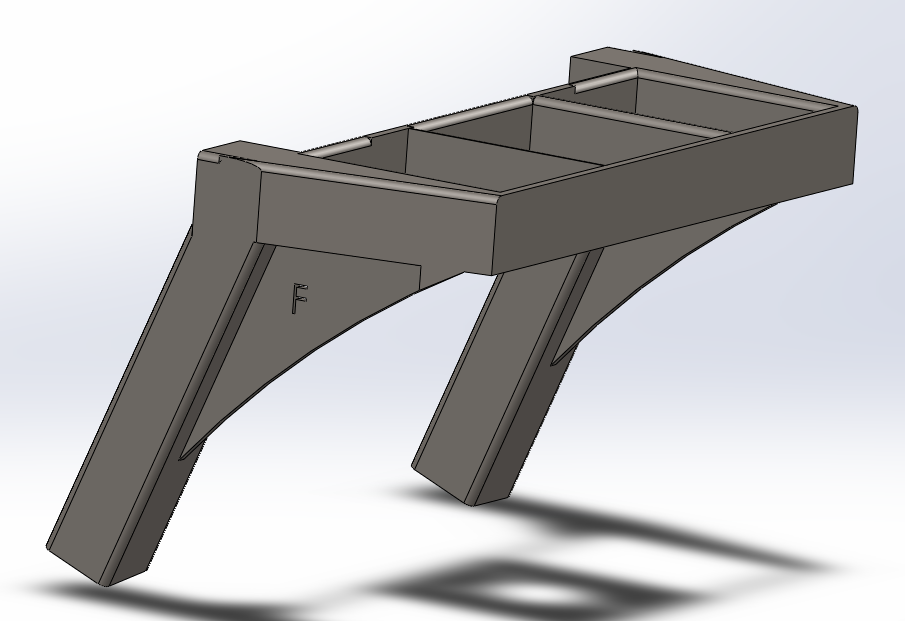

The target of our team’s design, “Carbon Overdraft”, is to utilize modern materials to maximize efficiency and capability by drastically reducing weight and applying tilt while turning principles to allow a better turning radius and faster speed capabilities through turns.

NOTE: This project is currently underway, and due to the competition involvement in the event, some preliminary design aspects have been blacked out to avoid use by other teams.

This Project is Sponsored by OSH Cut in Spanish Fork, Utah.

Competition Constraints & Design Requirements

Design decisions are governed by:

ASME eHPVC rules and safety requirements

Rider ergonomics and power delivery

Weight and structural efficiency

Manufacturing capabilities and budget limits

Timeline-driven iteration and testing

All design choices are validated against competition rules to ensure compliance while maximizing performance within allowable limits.

This environment closely mirrors real-world engineering programs where external requirements dictate design boundaries.

Mechanical Design & Analysis

Mechanical systems are being designed using analytical methods and iterative evaluation to balance strength, stiffness, and efficiency.

Engineering work included:

Structural layout and load path definition

Material selection and trade-off analysis

Component sizing based on expected loading

Integration of drivetrain and rider interfaces

Consideration of manufacturability and assembly sequence

Construction Materials

This design is comprised of two primary materials

Carbon Fiber

Used primarily in tube form, drastically reducing the vehicle’s weight without sacrificing strength.

Steel

Used primarily in load-critical areas like tubing joints, wheel knuckles, tilting mechanism ears, and pins

CAD design 1: Preliminary Wheel Knuckle

CAD Assembly ref 1: Dual ball joint connections for an additional degree of freedom

CAD Assembly ref 2: Parallelogram tilting mechanism

Fabrication & Assembly

The vehicle will be fabricated using in-house processes, requiring close coordination between design intent and manufacturing reality.

Key aspects included:

Translating CAD designs into manufacturable components

Managing tolerances and alignment during assembly

Iterative refinement based on fit-up and testing feedback

Ensuring all safety-critical features met inspection standards

This phase reinforces the importance of designing components that could be reliably built within real constraints.

Testing, Validation & Competition Performance

Testing and inspection will be used to validate both performance and compliance prior to competition.

This includes:

Functional testing of mechanical systems

Safety inspections and rule compliance checks

Performance evaluation during competition events

Iteration based on observed behavior and feedback

Competition performance provided direct, real-world validation of design assumptions.

Engineering Skills Required

Rule-driven mechanical design

Trade-off analysis under constraints

Team-based engineering coordination

Design-for-manufacturing principles

Validation through testing and competition

Technical communication and documentation

Key Engineering Takeaways

This project reinforces the importance of balancing theoretical design goals with regulatory requirements, manufacturability, and schedule constraints—an experience closely aligned with professional engineering practice.

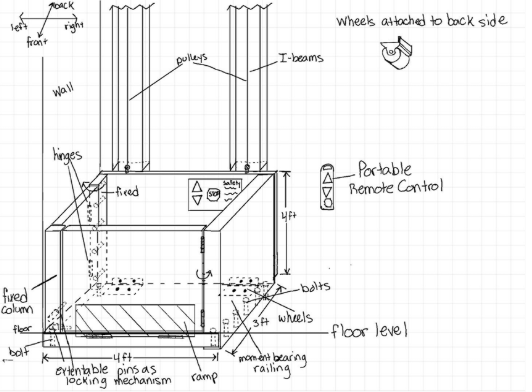

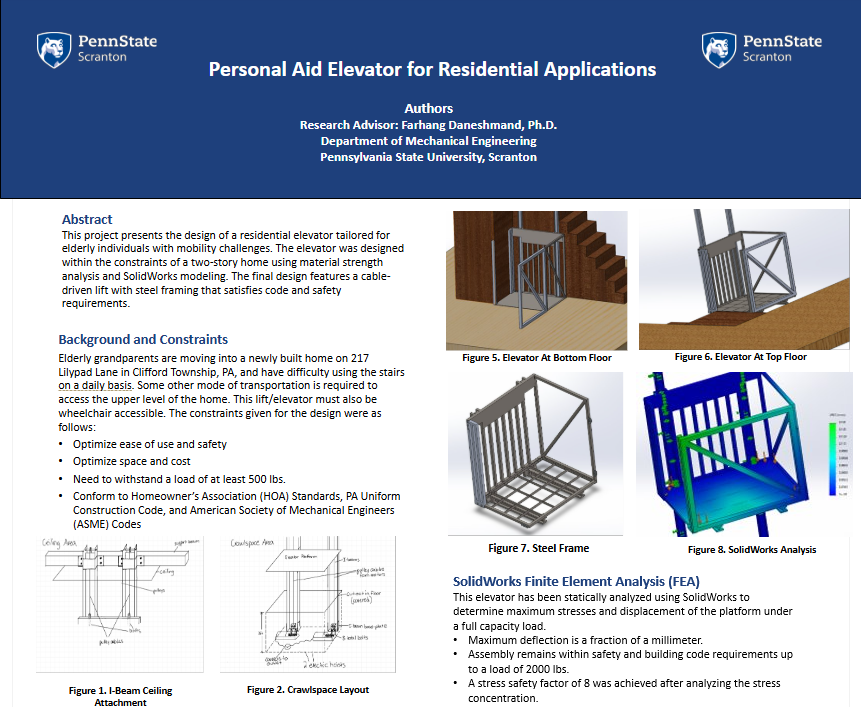

Elevator For Residential Applications

Design Constraints & Safety Considerations

The elevator/lift system was designed under the following constraints (as defined in the project requirements):

Accessibility: Must be wheelchair accessible and suitable for daily use by elderly occupants

Load Capacity: Must withstand a minimum rated load of 500 lb (passenger + mobility device + caretaker)

Safety Priority: Optimize for ease of use and safety as the primary design driver

Space + Cost: Optimize space usage and cost within a residential footprint

Compliance: Must conform to HOA requirements, the Pennsylvania Uniform Construction Code, and applicable ASME codes/standards

Engineering safety considerations guiding the mechanical design included:

Defined passenger/payload load cases and conservative assumptions

Static and dynamic loading conditions (start/stop, braking, and transient effects where applicable)

Safety factors appropriate for human-occupancy lifting systems

Fail-safe behavior and mechanical safeguards where feasible

Reliability under repeated operating cycles (durability, wear, and fatigue awareness)

All design decisions were evaluated through the lens of risk mitigation, prioritizing predictable behavior and safe operation over minimizing weight or cost.

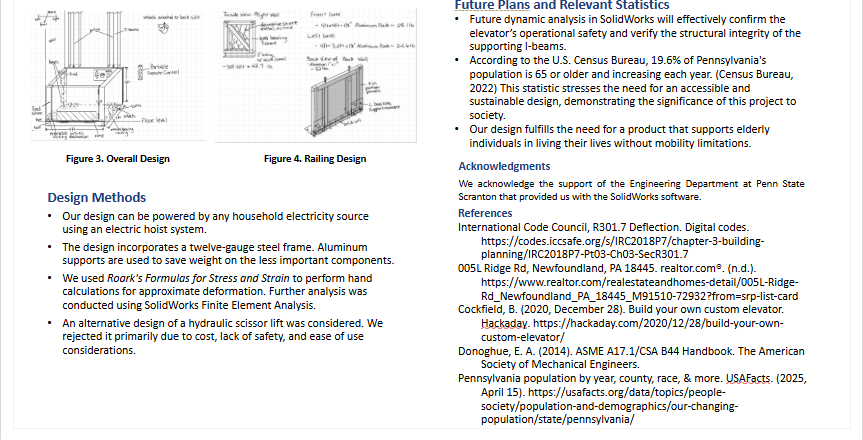

Project Overview

This project involved the mechanical engineering design and analysis of a residential elevator/lift system intended to improve accessibility in a two-story home environment. The primary goal was to create a system that is safe, reliable, space-efficient, and compliant with applicable codes, while meeting defined load and accessibility requirements.

The work focused on translating real-world functional needs into an engineered mechanical system, emphasizing failure prevention, predictable behavior, and long-term operability over aggressive optimization.

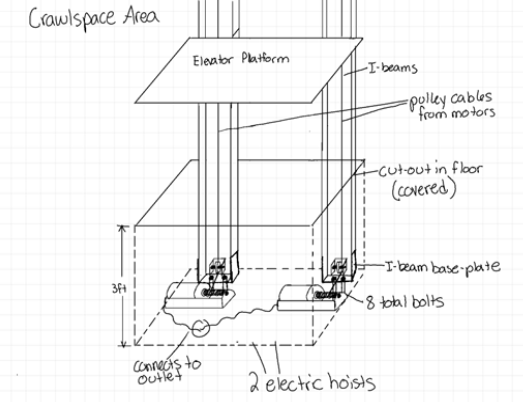

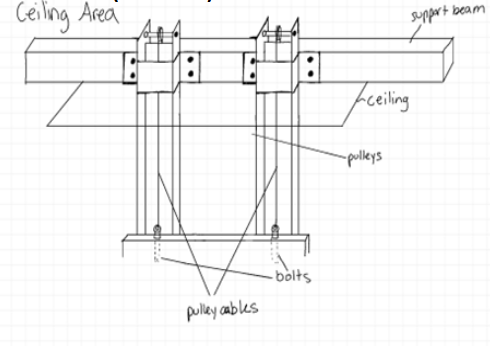

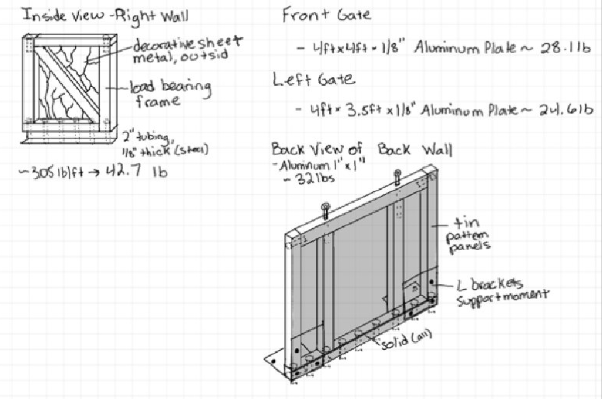

Mechanical Design & Analysis

The mechanical system was designed to support anticipated loads while maintaining structural integrity and alignment throughout the operating range.

Engineering work included:

Load path identification and force distribution

Component sizing based on expected stresses

Consideration of wear, fatigue, and long-term operation

Mechanical interface definition between subsystems

Evaluation of potential failure modes and mitigations

Analytical methods were used to ensure all primary components operated within acceptable limits under worst-case loading scenarios.

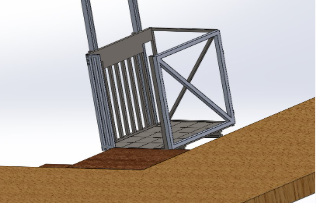

CAD Design: lowered/door open position

Design Drawing (1): Elevator Layout

Design Drawing (2): Electric lift system

Design Drawing (5): Upper Structure Support Method

Design Drawing (4): Decoration and safety panels

Safety-Critical Design Philosophy

Unlike performance-driven projects, this design prioritized:

Conservative assumptions

Redundant load paths where appropriate

Predictable mechanical behavior

Clear inspection and maintenance considerations

Design decisions favored robustness and clarity over sacrificing a large safety factor for better efficiency, reflecting professional best practices for systems involving human safety.

CAD Design: Rigid Steel Frame

CAD Design: raised position

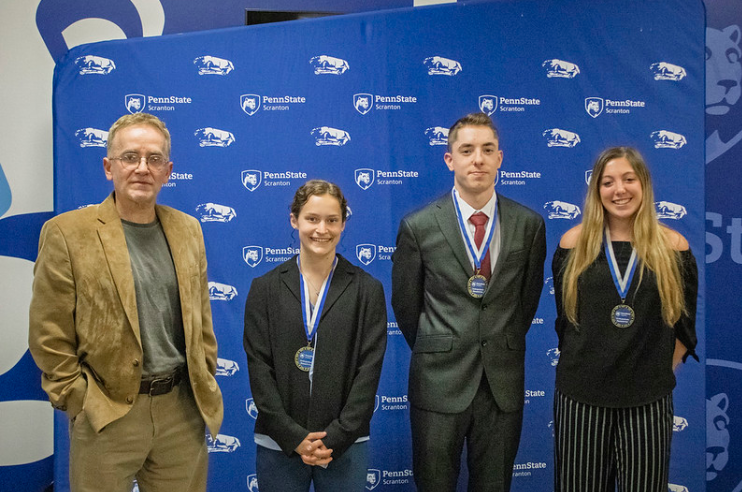

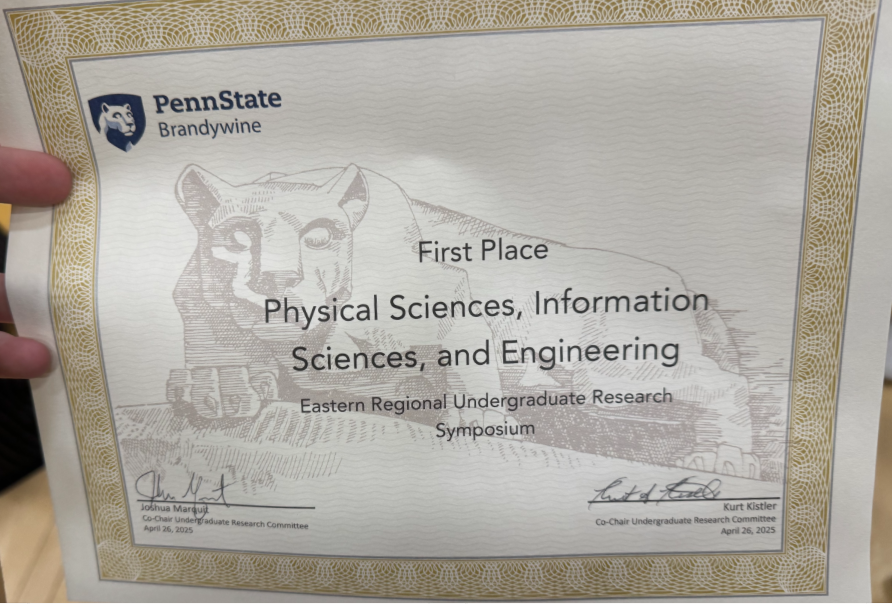

Awards & Recognition:

1st Place – Penn State Scranton Undergraduate Research Fair (spring 2025)

1st Place – Eastern Regional Research Symposium (Penn State Brandywine, spring 2025)

CAD Design: Finite Element Analysis

Undergraduate Research Fair, Penn State Scranton (Spring 2025)

Eastern Regional Research Symposium, Penn State Brandywine (Spring 2025)

Engineering Skills Demonstrated

Safety-critical mechanical design

Load and stress analysis

Constraint-driven decision making

Conservative engineering judgment

Failure mode awareness

Clear technical reasoning and documentation

Key Engineering Takeaways

This project reinforced the importance of disciplined engineering judgment when designing systems where reliability and safety are non-negotiable. It emphasized that good engineering is often defined not by maximum performance, but by predictable, repeatable, and safe operation under all expected conditions.